Crafting a fashion line, whether you're a seasoned pro or a new designer, can feel overwhelming. The process of turning a design into a finished garment involves many steps. To help you understand how a piece of clothing goes from concept to production, here's a guide to the current custom clothing manufacturing process.

The Clothing Manufacturing Process: A Modern Overview

The journey of a garment, from a sketch to a final product, is more streamlined and tech-driven than ever. Today's manufacturing process is collaborative and often relies on digital tools and automated systems to ensure efficiency, quality, and sustainability.

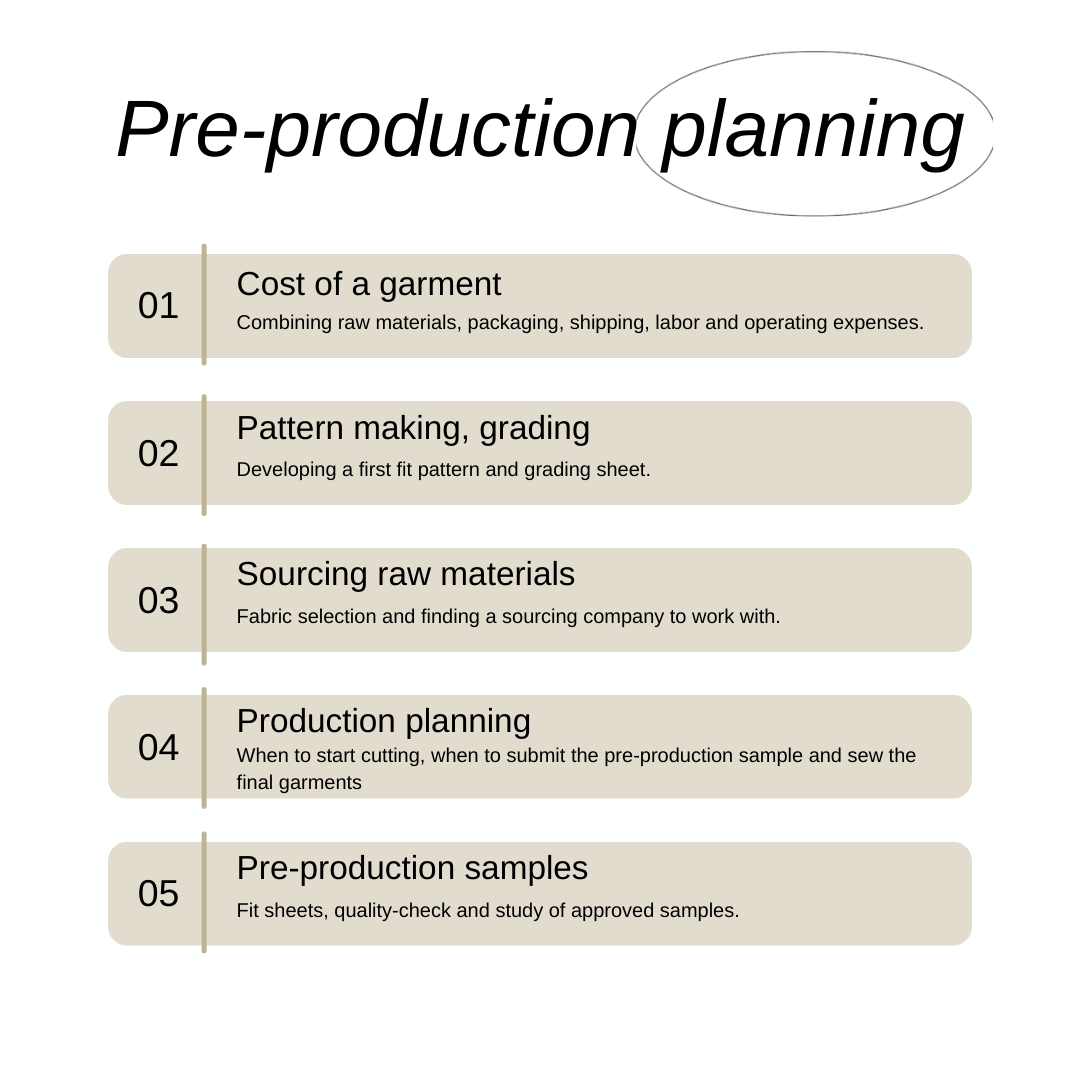

1. Pre-Production: The Digital Foundation

This initial phase is all about planning and preparation. It's the blueprint for the entire production run and is crucial for avoiding costly mistakes later on.

-

Design & Tech Packs: The process begins with a designer's vision. Instead of just a simple sketch, modern design relies on a tech pack (short for "technical package"). This digital document is the blueprint for a garment and is the primary communication tool between a designer and a manufacturer. A comprehensive tech pack includes:

-

Detailed flat sketches (front and back).

-

Fabric and trim specifications (buttons, zippers, labels).

-

Colorways and size breakdowns.

-

Detailed measurements and grading rules for different sizes.

-

Placement of logos, prints, or embroidery.

-

-

CAD Files: Computer-Aided Design (CAD) software is the industry standard for creating patterns, grading sizes, and laying out fabric markers for efficient cutting. This technology significantly reduces manual work, minimizes errors, and helps save on material waste.

-

Sourcing & Sustainability: Designers now have access to a global network of suppliers. Beyond just finding the right fabric (like cotton, linen, silk, or newer materials like Tencel and Modal), there's a growing emphasis on sourcing sustainable, eco-friendly, and recycled materials. This also includes selecting the right trims and accessories, from threads and buttons to zippers and labels. Many brands prioritize working with suppliers that use Azo-free or vegetable dyes for a lower environmental impact.

-

Sampling: This is the physical prototyping stage. Multiple samples may be created to perfect the design and fit before mass production.

-

Proto-sample: The very first sample, used to check the overall design and construction. It may use substitute materials.

-

Fit Sample: Made with the correct measurements to check the garment's fit on a model or mannequin.

-

Pre-Production (PP) Sample: The final, "golden" sample made with all the correct materials, trims, and finishes. No bulk production begins until this sample is approved.

-

2. Production: From Fabric to Finished Goods

Once the tech pack and samples are approved, the factory moves into full-scale production. Modern manufacturing prioritizes efficiency and quality control at every stage.

-

Fabric Inspection & Cutting: Fabric rolls are first inspected for any flaws. Then, the fabric is laid out in multiple layers, or "plies," often using automated spreading machines. Laser-cutting technology has become common, offering unmatched precision and minimal waste by optimizing how patterns are laid out on the fabric.

-

Embellishments & Printing: Processes like embroidery and screen printing are often done on flat fabric pieces before they are sewn together. Automated machinery allows for precise, repeatable designs.

-

Sewing: This is where the garment takes shape. Cut pieces are bundled by size and color and then sewn together in an assembly line. Each operator is responsible for a specific task, ensuring consistency. Modern sewing floors use a variety of specialized machines to increase efficiency.

-

Quality Control: Quality checks are performed at multiple points. In-line inspections catch errors as they happen, and a final inspection ensures the finished garment meets all quality standards. This includes checking things like:

-

Garment Dimensions: Ensuring the final product matches the measurements specified in the tech pack.

-

Accessory Functionality: Testing zippers, buttons, and snaps for durability and proper attachment through things like pull and fatigue tests.

-

Fabric Quality: Checking for defects, consistent color, and making sure the fabric meets density standards (GSM, or grams per square meter).

-

Stitch Quality: Counting stitches per inch (SPI) to ensure a strong, durable seam.

-

Material Composition: Verifying that the fabric blend matches what is listed on the care label, often through third-party lab testing.

-

3. Post-Production & Delivery

The final stages focus on getting the product ready for the end customer.

-

Packaging: Garments are folded, packed in polybags, and then placed in boxes. Sustainable packaging, like biodegradable polybags and recycled cardboard, is a growing trend. Cartons are marked with detailed information (size, color, destination, etc.) to streamline logistics.

-

Delivery & Logistics: The goods are shipped to the brand. The terms of this shipment, such as who is responsible for costs and liability, are decided by the shipping agreement.

-

Free on Board (FOB): The seller is responsible for the goods until they are loaded onto the ship or aircraft.

-

Cost, Insurance, and Freight (CIF): The seller is responsible for the goods until they arrive at the buyer's destination port.

-

As you can see, the modern clothing manufacturing process is a blend of creative design, meticulous planning, and technological execution. It requires a strong, collaborative partnership between the designer and the manufacturer to ensure a high-quality product is delivered on time.